Analysis: How Will Material Scarcity Affect EV Production?

[ad_1]

Electric Vehicle Growth Is Pushing Content Requires

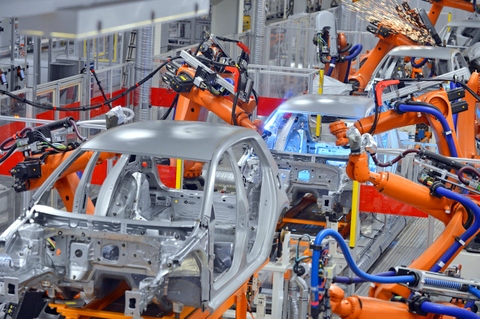

When most individuals believe about effortless means to lessen their carbon footprint, just one of the most widespread solutions is to switch their gasoline-guzzling every day driver with an electric powered auto. Buying an EV is reasonably simple, if a little bit additional pricey than an inner combustion engine vehicle or truck, but that may well not be the case in the foreseeable future. How will materials shortage have an affect on EV manufacturing going ahead?

Having difficulties With Semiconductor Shortages

Most of the contemporary technological know-how that helps make the world purpose relies on semiconductors. Without these elements, it’s difficult to create the chips that make every thing from cellphones to EVs function.

The chip lack started in 2020 because of to trade conflicts between the United States and China and was created even worse by the COVID-19 pandemic. Most of the world’s chip producing capabilities exist in Asia.

Gurus estimate that the chip scarcity will most likely carry on via 2023 and into 2024 in advance of issues begin to even out. The chip shortages are now hitting the equipment applied to manufacture the chips, main to even far more supply issues and producing it tougher to meet up with the developing need.

Missing Some Essential Products

The COVID-19 pandemic prompted all kinds of matters to vanish from store shelves, commencing with cleaning supplies and bathroom paper and biking as a result of almost everything from soda to product cheese and little one method over the final two several years. Even beer disappeared from store cabinets as companies contended with an aluminum lack.

It may possibly not appear as crucial as the semiconductors applied to make personal computer chips or the exceptional earth metals used to make EV batteries, but an aluminum scarcity can be as impactful. Extruded aluminum is a popular selection for automotive producing mainly because it makes it possible for engineers to style strong and lightweight frames. Devoid of aluminum, manufacturers could be forced to return to steel for their building, which will minimize the variety of EVs, making them significantly less powerful overall.

Battery Raw Material Shortages

An EV is only as excellent as its battery and the supplies important to produce the significant lithium-ion battery packs that electricity these motor vehicles are in brief source. It is turning out to be a lot more and additional tough to harvest and refine the manganese, nickel and lithium needed to build these batteries.

Now, the world’s battery creation is one particular-tenth of what it wants to aid envisioned EV progress over the subsequent decades. Some in the automotive business get worried that if new methods aren’t discovered, these shortages won’t just slow the adoption of EVs—they could halt it solely.

Securing the Long run of EVs

There are probable alternatives on the horizon. Tesla, for case in point, not long ago utilized for a permit to open a processing plant in Texas that can refine spodumene focus into usable lithium hydroxide for its EV batteries.

Still, there is not currently more than enough provide to assistance the at any time-raising need. Manufacturers will will need to find new answers if they hope to make EVs a lot more available to the masses.

Much more EV Information:

Tesla Opens New Plant Promises New Product

Welcome to the Yr of the EV

[ad_2]

Resource link