Standardized automotive show connectivity framework

The automotive show connectivity challenge

Automotive exhibit devices are at the moment undergoing accelerated evolution because of to field tendencies in connectivity, automation, sharing and electrification. Superior driver-support methods (ADAS), digital cockpits, in-car or truck infotainment (IVI) and autonomous driving techniques (Advertisements) are driving a swift proliferation in the amount of in-vehicle shows and the need to have for ever-expanding display screen resolutions, frame fees and coloration bit-depths.

The resultant multigigabit internet knowledge throughputs necessary to connect all of these shows current a major layout concern for foreseeable future automobiles, demanding the enhancement of impressive electrical and electronic (E/E) architectures that leverage the most current display systems. These state-of-the-art display programs need to also meet the stringent dependability, electrical power, excess weight and electromagnetic compatibility (EMC) requirements demanded by the automotive marketplace.

Raising figures of in-car or truck shows. Source: MIPI

The use of sector standards for displays has solved related worries in adjacent industries this sort of as cellular phones, and this posting will reveal how following a criteria-based method is also essential to solving the automotive exhibit connectivity challenge.

Prime five specialized issues for connecting automotive shows

The obstacle of automotive display screen connectivity raises 5 principal specialized concerns that have to have to be tackled when developing automotive E/E architectures:

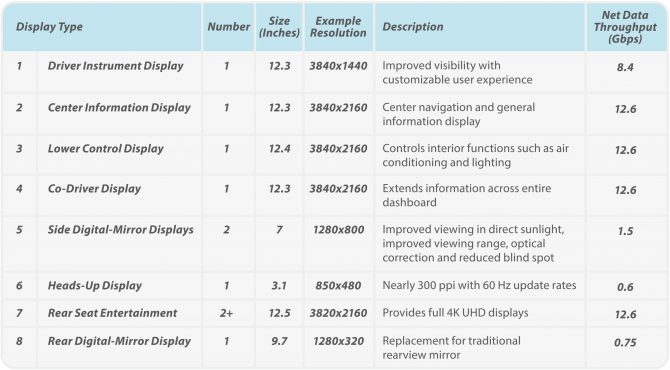

- Bandwidth and latency: As demonstrated in the picture and table, far more displays are staying integrated into motor vehicles to aid the expanding demand from customers for ADAS and Ads —replacing conventional analog instrument clusters, mirrors and mechanical buttons, and incorporating new shows to assistance IVI solutions and to help electronic auto customization. The growing quantity of shows mixed with at any time-increasing exhibit resolutions, frame costs and colour bit-depths will require multigigabit-for each-2nd, extremely-reduced-latency connectivity, with the full internet data throughput essential to connect shows predicted to boost appreciably with just about every new era of vehicles.

- Electromagnetic interference (EMI) immunity: Harsh in-motor vehicle environments present substantial problems to multigigabit conversation technologies, which are demanded to function at significantly bigger symbol premiums and at considerably better in-band frequencies. To guarantee safe and sound and resilient operation of high-throughput info inbound links around the vehicle’s lifespan, communications inbound links have to deliver ultra-significant immunity to any EMI outcomes by employing sound cancellation and mistake correction mechanisms that focus on the negative results of automotive EMI.

- Cable harness complexity: The cable harness is presently 1 of the heaviest and most costly factors in a automobile. Connectivity options for in-car or truck shows should, where ever achievable, decrease the complexity of the cable harness, lessening the cable shielding and amount of conductors to a minimal to conserve price tag and pounds, and allowing for use of inline connectors to help simplicity of set up on the creation line. Connectivity options will have to also protect from cable harness degradation owing to cable growing older and flexing.

- Functional safety enablers: ADAS and Advertisements programs should satisfy Automotive Safety Integrity Stage (ASIL) needs, from ASIL B through ASIL D, as described inside ISO 26262. Capabilities that allow purposeful basic safety inside of screen connectivity methods to detect loss of packets, frozen back links and loss of conversation are crucial to meet up with these stringent necessities.

- Engineering exertion: Integrating superior displays into automobiles can require the use of quite a few distinct program and components components, sourced from numerous different distributors. Creating bespoke connectivity remedies in-household, or with a constrained number of suppliers, can substantially boost engineering effort and hard work and part fees, placing the total price tag stress, like enhancement, check and validation, on to a one automaker.

-

Illustration in-auto display screen forms and web info throughputs. Source: MIPI

How a standardized automotive screen connectivity framework can conquer these troubles

Use of a standardized automotive display screen connectivity framework, these kinds of as the one furnished by the MIPI Automotive SerDes Methods (MASS) show specs, can help automakers conquer all of the issues explained over. Not like personal requirements, which address only 1 part of a display screen answer (such as just supplying the physical layer), a framework option presents physical and protocol layers collectively with important features such as screen stream compression and useful basic safety enablers, developing a fully built-in alternative for the automotive industry.

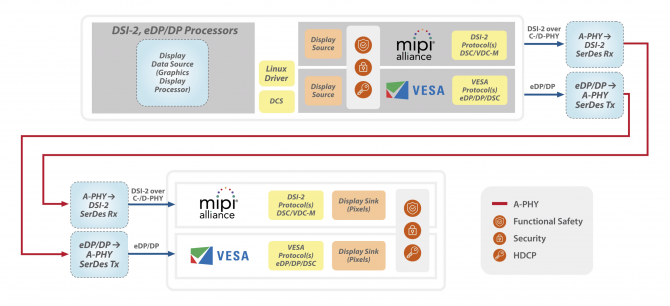

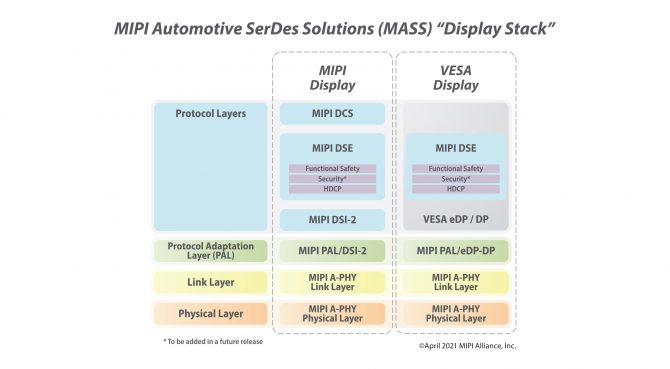

The MASS show framework, proven above, provides a complete automotive connectivity remedy, incorporating a suite of field specs:

* MIPI A-PHY: A high-velocity, very low-latency (< 6?s), long-reach (up to 15m) asymmetric serializer/deserializer (SerDes) physical layer interface. A-PHY employs dynamic pulse amplitude modulation, just-in-time interference cancellers and PHY-level retransmission mechanisms to ensure ultra-high noise immunity and maximum link robustness. It supports heterogeneous point-to-point and daisy-chain display topologies and optional power delivery over a single cable (coaxial or shielded twisted pair), eliminating the need for proprietary asymmetric PHYs, simplifying in-vehicle communication networks and reducing cost, cable harness weight and development time.

MIPI Automotive SerDes Solutions (MASS) display connectivity example. Source: MIPI

* MIPI Protocol Adaptation Layers (PALs): Specifications that allow display components based on MIPI Display Serial Interface 2 (MIPI DSI-2) and VESA Embedded DisplayPort and DisplayPort (VESA eDP/DP) protocols to map their video, audio and control data to A-PHY’s A-Packet format for transmission over long-reach A-PHY networks.

* MIPI DSI-2 and VESA eDP/DP: Industry-leading display protocols to enable long-reach source-to-sink connectivity between automotive displays and their associated electronic control units. Already extensively adopted within multiple industries, including mobile, computer and automotive, use of these protocols dramatically reduces engineering effort and cost.

* MIPI Display Service Extensions (MIPI DSE): A new specification that standardizes functional safety enablers to help display solutions meet ISO 26262 requirements from ASIL B to ASIL D. Enablers include link failure detection, timeout monitoring, cyclic redundancy check to detect data transmission failures, and a message counter for replay protection. High-bandwidth Digital Content Protection (HDCP) is also enabled by DSE, and additional security features will be added in future releases.

* MIPI Display Command Set (MIPI DCS): A standardized command set for control functions and supply of data to displays using MIPI DSI-2. It specifies commands for setup, control and test functions, including the control of settings such as resolution, width and brightness, thus significantly simplifying integration and design cost.

* VESA Display Stream Compression (DSC) and VESA Display Compression-M (VDC-M): Incorporated into DSI-2, codecs that offer guaranteed low-latency performance and are visually lossless for images and videos (DSC at 8 bits-per-pixel compression and VDC-M at 5-6 bits-per-pixel compression). Already widely adopted within multiple industries, including mobile and the Internet of Things (IoT), use of these standard compression technologies for automotive display applications not only massively reduces connectivity bandwidth, but also dramatically reduces engineering effort and cost.

MIPI Automotive SerDes Solutions (MASS) display specifications. Source: MIPI

Conclusion

Use of industry standards such as MASS solves key automotive display connectivity challenges, drives interoperability between different vendor solutions and leverages economies of scale by amortizing engineering costs over larger volumes of components spread across the whole industry. Most importantly for automakers, the use of standards removes the burden of designing (or selecting) a proprietary interface for the next E/E architectures, allowing automakers to focus on “higher-value,” product-differentiating technologies that sit higher up the protocol stack.

—————————-

This article was written and submitted by James Goel, MIPI technical steering group chair and display working group vice chair. Read more about the MIPI Automotive SerDes Solutions display framework.